What is a Supply Chain ERP System?

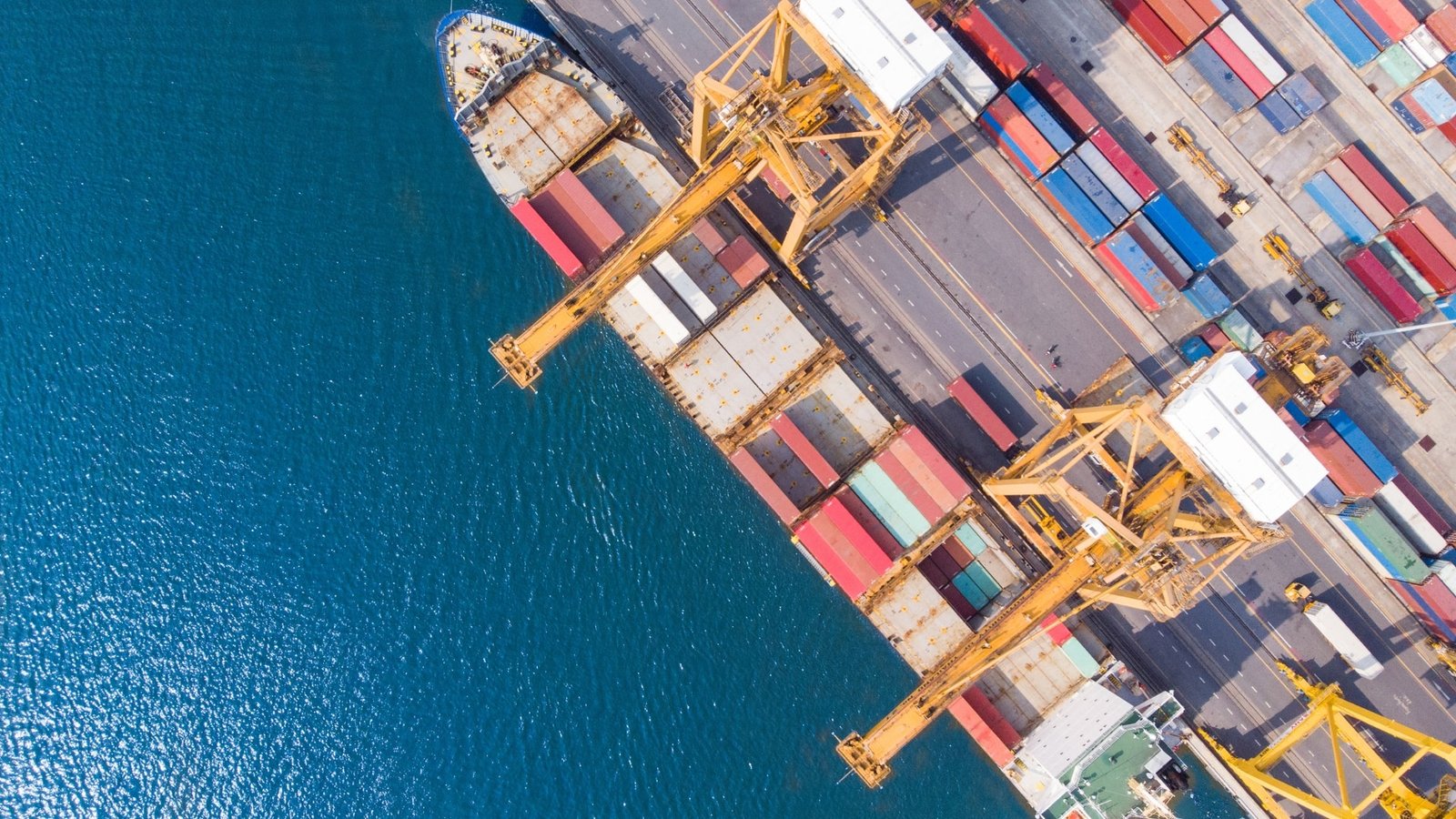

Having worked with companies that have dealt with manufacturing and supply chain in the defense and aviation industry, the supply chain bit is the most important. You can’t manufacture without raw materials and to get the raw materials, you need to have a perfect supply chain.

Now I know, you will say, achieving a perfect supply chain is impossible. Noel, I cannot predict what’s going to happen. Yes, you are right, you cannot predict, but you can reduce the risk by having the right systems that help to streamline the process.

Enterprise resource planning (ERP) systems play a crucial role in modern supply chain management by integrating and optimizing various functions such as, sourcing materials procurement, manufacturing, warehousing, and logistics. The supply chain management process is integral to transforming raw materials into finished products and handling returns efficiently.

These systems help organizations understand their supply chain and its impact on manufacturing. Supply chain management involves planning how organizations supply components and materials across the entire flow of goods or services.

Key Components of a Supply Chain ERP System

Demand and Planning

An ERP system with Supply Chain Management (SCM) capabilities creates automatic supply chain tasks and demand forecasts using historical and real-time data to improve supply chain management. They help organizations determine the quantity of materials, products, and resources required, including labor.

Supply chain management involves planning how organizations supply components and materials across the entire flow of goods or services. ERP systems enhance visibility, coordination, supply chain adaptability, and efficiency across the entire supply chain.

Sourcing and Procurement

An ERP system with Material Requirements Planning (MRP) capabilities synchronizes demand with the materials required to produce products. They help organizations identify the necessary suppliers, sub-contract manufacturers, and distributors.

Supply chain management also involves procuring materials and identifying the necessary suppliers, sub-contract manufacturers, and distributors. The ERP systems house all vendor information in one system for easy access and integrating supply chain management software can automate supply chain activities and optimize operations to meet customer demands while minimizing costs.

Production and Manufacturing

An ERP system like SAP (and I’m talking about Enterprise grade) helps organizations effectively execute a production schedule by housing all production information, which is a crucial aspect of the ERP system maintains supply chain management.

Supply chain management involves managing the capacity you have across production lines and who you can outsource/sub-contract to for specialty supply chain functions or overflow. The ERP systems track shipments and display the quantity and number of items shipped. They link support and shipping to further improve efficiency of the speed and timeliness of delivery.

Delivery and Logistics

Effective supply chain management strategy involves maintaining relationships with shipping carriers who can provide predictable delivery to meet promised delivery dates, especially within the context of supply chains. An ERP system with Distribution Requirements Planning (DRP) capabilities tracks shipments and displays the quantity and number of items shipped.

ERP systems link support and shipping to improve the speed and timeliness of delivery. Supply chain management involves managing the movement of goods around a business and connecting the sources of supply and customer demand.

Benefits of a Robust Supply Chain ERP System

So, what does this mean for companies, you might ask? Implementing an ERP system for supply chain and financial management offers numerous advantages:

-

Improved Supply Chain Efficiency: By automating supply chain activities and streamlining processes, ERP systems significantly enhance overall supply chain efficiency.

-

Cost Savings: ERP solutions help reduce operating costs through better inventory management, optimized production processes, and improved resource allocation.

-

Enhanced Adaptability: With scenario planning capabilities and real-time data, ERP systems enable businesses to quickly adapt to changes in consumer demand or market conditions.

-

Increased Visibility: ERP integration provides end-to-end visibility across supply chains, allowing businesses to identify and address potential disruptions proactively.

-

Better Customer Service: By maximizing product availability and ensuring on-time delivery, ERP systems help improve customer satisfaction and loyalty.

-

Data-Driven Decision Making: With access to real-time data and advanced analytics, ERP solutions empower businesses to make informed decisions about their supply chain operations.

-

Scalability: As businesses grow, ERP systems can scale to accommodate increased complexity in supply chain operations and support business expansion.

Optimizing Supply Chain Operations with ERP Systems

ERP systems can enhance supply chain management at every stage, from planning and procurement to inventory management and delivery. ERP systems streamline supply chain business processes throughout, enhancing efficiency and reducing costs.

These systems provide real-time data and visibility into supply chain operations, enabling better decision-making. ERP systems help businesses optimize supply chain management processes, leading to improved customer satisfaction. ERP systems enable businesses to automate supply chain operations, reducing the risk of human error.

Implementing a Supply Chain ERP System

Cloud-based ERP solutions are a better fit than on-premises systems for many businesses due to scalability and ease of implementation, especially when considering the role of an ERP system in supply chain management. Selecting the right ERP and supply chain management system is crucial for effective implementation.

-

ERP systems should be selected based on functionality, scalability, and implementation complexity.

-

Companies should consider future business growth and needs when selecting an ERP system.

-

ERP systems should be integrated with specialized supply chain applications and cloud ERP features.

What are the Main Supply Chain ERP Solutions

Enterprise Resource Planning (ERP) systems play a crucial role in managing complex supply chain business operations. Several ERP solutions cater specifically to supply chain management needs, offering features that streamline processes, enhance visibility, and improve decision-making. Here are some of the main supply chain ERP solutions:

1. SAP S/4HANA

SAP S/4HANA is widely regarded as one of the most comprehensive ERP solutions for supply chain management. It offers:

-

Advanced analytics for real-time insights

-

Streamlined processes across procurement, inventory, and logistics

-

Seamless integration with other SAP products and third-party applications

SAP S/4HANA is particularly suitable for large enterprises with complex, global supply chains.

2. Oracle NetSuite

Oracle NetSuite is a cloud-based ERP solution popular among small to mid-sized businesses. Its supply chain features include:

-

Real-time inventory management

-

Demand planning and forecasting

-

Order management and fulfillment

NetSuite’s scalability makes it an excellent choice for growing businesses.

3. Microsoft Dynamics 365 Supply Chain Management

Microsoft’s offering provides:

-

End-to-end visibility across planning, production, inventory, warehouse, and transportation

-

AI-driven insights for demand forecasting

-

Integration with other Microsoft tools like Office 365

-

Flexible deployment options (cloud, on-premises, or hybrid)

4. Infor CloudSuite Industrial

Infor CloudSuite Industrial, formerly known as SyteLine, is tailored for manufacturing and distribution industries. It offers:

-

Advanced planning and scheduling

-

Quality management

-

Multi-site and multi-currency support

-

Strong inventory control features

5. Epicor ERP

Epicor ERP is known for its strong manufacturing and distribution capabilities. Its supply chain features include:

-

Material Requirements Planning (MRP)

-

Supplier relationship management

-

Inventory optimization

-

Global trade compliance tools

6. IFS Applications

IFS Applications provides a comprehensive suite of ERP functions, with robust supply chain capabilities such as:

-

Demand planning

-

Supply chain planning

-

Global trade management

-

Warehouse management

It’s particularly strong in asset-intensive and project-based industries.

7. Sage X3

Sage X3 offers supply chain risk management features suitable for mid-market companies:

-

Procurement management

-

Inventory management

-

Sales management

-

Manufacturing management

8. Acumatica Cloud ERP

Acumatica provides a flexible, cloud-based ERP solution with supply chain features including:

-

Inventory management

-

Purchase order management

-

Sales order management

-

Warehouse management

Its unique pricing model, based on transaction volume rather than user count, can be advantageous for some businesses.

9. SYSPRO

SYSPRO is an ERP solution focused on manufacturing and distribution industries. Its supply chain capabilities include:

-

Inventory optimization

-

Demand forecasting

-

Supplier performance management

-

Lot traceability and serial tracking

10. Odoo

Odoo is an open-source ERP solution that offers modular functionality, including supply chain and inventory management capabilities and features like:

-

Inventory management

-

Purchase management

-

Manufacturing management

-

Warehouse management

Its open-source nature allows for extensive customization.

When choosing a supply chain ERP solution, businesses should consider factors such as their industry, size, specific supply chain needs, budget, and existing IT infrastructure. Many of these solutions offer industry-specific versions or modules, allowing for tailored functionality that addresses unique supply chain challenges.

It‘s also important to consider factors like ease of implementation, user-friendliness, scalability, and the availability of local support when selecting an ERP system for supply chain management. As supply chains become increasingly complex and global, choosing the right ERP solution can provide a significant competitive advantage by improving efficiency, reducing costs, and enhancing overall supply chain performance.

Best Practices for Supply Chain ERP Implementation

-

Identify the right ERP solution for your business needs.

-

Develop a clear implementation plan and timeline.

-

Provide training and support for employees.

-

Monitor and evaluate the effectiveness of the ERP system.

Effective customer relationship management (CRM) is also crucial, as it integrates with various other supply chain tasks and management functions to enhance overall performance and efficiency.

Choosing the Right ERP Solution for Supply Chain Management

When selecting an ERP system for supply chain management, consider the following factors:

-

Industry-specific functionality: Look for ERP solutions tailored to your industry, whether it’s manufacturing, distribution, or retail.

-

Cloud vs. On-premise: Evaluate whether a cloud ERP or on-premise solution best fits your organization’s needs and IT infrastructure.

-

Integration capabilities: Ensure the ERP system can integrate seamlessly with existing software systems and supply chain partners.

-

Scalability: Choose an ERP solution that can grow with your business and adapt to changing supply chain needs.

-

User-friendliness: Opt for an ERP system with an intuitive interface to facilitate user adoption and maximize efficiency.

-

Analytics and reporting: Look for robust business intelligence and reporting features to gain actionable insights from your supply chain data.

-

Mobile accessibility: Consider ERP solutions that offer mobile apps for on-the-go access to critical supply chain information.

Main Considerations When Implementing Supply Chain ERP Solutions

Implementing a supply chain ERP solution is a complex undertaking that requires careful planning and execution. Based on my experience working with various ERP systems in manufacturing industry, including SAP, Microsoft, and Oracle, here are the key considerations organizations should keep in mind:

1. Clear Definition of Objectives and Scope

Before embarking on an implementation, it’s crucial to:

-

Define specific, measurable goals for the supply chain ERP implementation

-

Clearly outline the scope of the project, including which processes and departments will be affected

-

Align the implementation objectives with overall business strategy

2. Stakeholder Engagement and Buy-in

Success hinges on getting all relevant parties on board:

-

Secure executive sponsorship to ensure top-level support

-

Involve key stakeholders from different departments early in the process

-

Create a cross-functional implementation team to represent various perspectives

3. Data Management and Migration

Data is the lifeblood of any ERP system. Consider:

-

Conducting a thorough data audit to identify what needs to be migrated

-

Cleaning and standardizing data before migration to ensure accuracy

-

Developing a robust data governance strategy for ongoing data management

4. Process Reengineering and Standardization

ERP implementation often requires rethinking existing processes:

-

Map current supply chain processes and identify areas for improvement

-

Standardize processes across different locations or business units where possible

-

Be prepared to adapt processes to fit ERP best practices rather than over-customizing the software

5. Integration with Existing Systems

Consider how the new ERP will work with your current technology stack:

-

Identify all systems that need to integrate with the ERP

-

Plan for necessary middleware or custom integrations

-

Ensure seamless data flow between systems to avoid silos

6. Change Management and Training

People are key to successful implementation:

-

Develop a comprehensive change management strategy

-

Provide thorough training for all users, tailored to their specific roles

-

Create user guides and support resources for ongoing reference

7. Phased Implementation Approach

Consider a phased rollout to manage complexity:

-

Start with core functionalities and gradually add more advanced features

-

Implement in one region or business unit before expanding

-

Allow time for stabilization and lessons learned between phases

8. Performance Metrics and KPIs

Establish how you’ll measure success:

-

Define key performance indicators (KPIs) aligned with your objectives

-

Set up dashboards and reporting tools to track these metrics

-

Plan for regular performance reviews and continuous improvement

9. Vendor Selection and Management

Choose your ERP vendor and implementation partner carefully:

-

Evaluate vendors based on industry expertise, support capabilities, and long-term viability

-

Clearly define roles and responsibilities in the implementation contract

-

Establish a strong governance structure for vendor management

10. Scalability and Future-proofing

Think beyond immediate needs:

-

Choose a solution that can scale with your business growth

-

Consider future technological advancements (e.g., AI, IoT) and how the ERP can adapt

-

Plan for regular updates and upgrades to keep the system current

11. Compliance and Security

Ensure your implementation meets all necessary standards:

-

Address industry-specific compliance requirements

-

Implement robust security measures to protect sensitive supply chain data

-

Consider data privacy regulations, especially for global supply chains

12. Total Cost of Ownership (TCO)

Look beyond initial implementation costs:

-

Factor in ongoing maintenance, support, and upgrade costs

-

Consider potential productivity gains and ROI over the long term

-

Budget for unexpected costs and contingencies

By carefully considering these factors, organizations can significantly increase their chances of a successful supply chain ERP implementation. Remember, the goal is not just to implement new software, but to transform and optimize your supply chain operations for long-term success.

Overcoming Common Challenges in Supply Chain ERP Implementation

-

Managing change and resistance to new technology, especially when implementing an enterprise resource planning system.

-

Ensuring data accuracy and integrity.

-

Integrating with existing systems and applications.

-

Providing ongoing support and maintenance.

Conclusion

-

A robust supply chain ERP system is essential for modern supply chain management.

-

ERP systems can help organizations optimize supply chain operations, improve visibility and coordination, and enhance customer satisfaction.

-

By implementing a supply chain ERP system, businesses can improve their competitiveness and achieve long-term success.

Subscribe to our website to get more information on all the technology information you need.

Also Read: What is ERP System in Accounting and How Does it Work? – Tech News Before It’s News | Shift GearX

You will also love: Top 10 Warehouse Management Software for SMBs in 2024! – Tech News Before It’s News | Shift GearX

Subscribe to Shift GearX for more Information.